Mud Pump 365GPM

Model: PM365

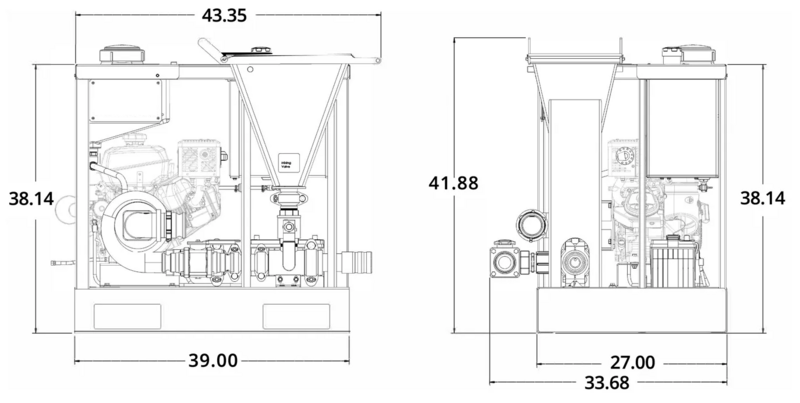

Compact Footprint – 42″ Tall, 34″ Deep, 39″ Base Width, 44″ Overall Width

365-GPM Pump

14 HP Kohler engine

High-speed jet and venturi

Produces yielded mud in minutes

Pairs with SL1000-gallon mix system tank

Model: PM365

Compact Footprint – 42″ Tall, 34″ Deep, 39″ Base Width, 44″ Overall Width

365-GPM Pump

14 HP Kohler engine

High-speed jet and venturi

Produces yielded mud in minutes

Pairs with SL1000-gallon mix system tank

Model: PM365

Compact Footprint – 42″ Tall, 34″ Deep, 39″ Base Width, 44″ Overall Width

365-GPM Pump

14 HP Kohler engine

High-speed jet and venturi

Produces yielded mud in minutes

Pairs with SL1000-gallon mix system tank

Product Details

The Most Complete Bentonite Mud Mixing System in Its Class

MP365 Mixer, a cutting-edge compact mud mixing solution that sets new standards in horizontal directional drilling (HDD) operations. This exceptional mixer is engineered to revolutionize the drilling process by delivering unparalleled efficiency and versatility. Equipped with a 365-GPM, 14 HP Kohler engine, surpasses expectations with its state-of-the-art features and advanced capabilities, making it an indispensable tool for HDD professionals. Not to mention, our suppliers field-proven high-speed jet and venturi produce sheared and yielded mud in minutes.

Its exceptional mixing power and adaptability that sets this mixer apart from the competition. Equipped with a robust mixing pump, this mixer combines various additives and water to create a consistently blended drilling mud. Its impressive mixing capacity allows for the processing of large volumes of drilling fluids, significantly reducing downtime and enhancing overall productivity on the job site.

Designed for Ultimate Control and Precision

Featuring an intuitive control panel that enables operators to fine-tune mixing parameters according to specific project requirements. This level of customization ensures optimal viscosity and consistency of the mud, resulting in improved drilling performance and accuracy. Whether dealing with bentonite, polymers, or other additives, this mixer effortlessly handles a wide range of drilling fluids, making it a versatile solution for various HDD applications.

Certainly, the MP365 excels in performance and prioritizes operator safety and ease of use. Furthermore, the ergonomic design and accessible maintenance points enhance operator convenience and reduce downtime associated with upkeep.

Overall, no matter the size of your upcoming HDD projects, this Mixer delivers exceptional performance and reliability. Its advanced features, robust construction, and dedication to operator safety cement its position as a market-leading solution in the horizontal drilling industry. Experience the next generation of mud mixing technology