Cable Plow Blades

Maverick, Inc. is proud to supply affordable yet durable plow blades for cable plows for industry-leading brands such as: Ditch Witch® , Vermeer®, Case, Astec, Toro®, Delta & More!

Maverick, Inc. has extensive experience selling and servicing Ditch Witch® cable plow machines. When it comes to plow blades for underground line installation, we’re extend that knowledge to other models of cable plow. Experts? We know a lot. Any brand, from the smallest to the biggest we are able to provide it. Vibratory plows are the ideal, cost-effective, efficient solution for residential fiber installation, cable, and lawn irrigation. Save time and energy while plowing pipes and cables at depths ranging from 6 inches to 42 inches. Not only is vibratory plowing easier than trenching or digging, but it also creates less mess while allowing you to work in tight spaces.

Quality First!

Our manufacturing facility specializes in the production of both standard and custom-made plow blades. We are able to configure patterns for current, older, and even discontinued machines. Utilizing decades of experience to get you what you need. We pride ourselves on efficiently supplying quality products that perform and in a timely manner.

Biggest To Smallest!

From Large Ride-on plows, to walk behind and pedestrian machines we’ve got you covered. There is a wide variety of utility installation applications. ranging from gas, fiber, water, and electric. We have applications for underground cable installation include: Cable TV, Fiber Optic Cables, Phone Lines. Plus: Irrigation, Electric Wiring, Gas Lines, Drainage Systems, Duct or Innerduct & More!

We get It!

There is not an App for some things. Determination, hard work and ingenuity are the tools needed to get product in the ground. We apply that philosophy to everything we do. It is always our goal to understand and meet the needs of our customers, making the effort to get it right the first time, so they can do what they do best.

Order Information Guide

A) Determine the Make of your machine (Ditch Witch®, Vermeer®, Case, Astec or Toro®, Delta, ETC…) and plow attachment number.

B) Know what material you will be burying, outside dimension (referred to as O.D.), and application in which the material will be used (such as Electric, Fiber, Water, Duct, etc…).

C) Figure out what depth the material will be buried at. This is referred to as the cover, or cover depth.

D) Know whether the material will be pulled in or fed through A chute blade. Note: Diameter of Product and multiple Ducts are helpful in determining Bullet/Expander or Chute Size.

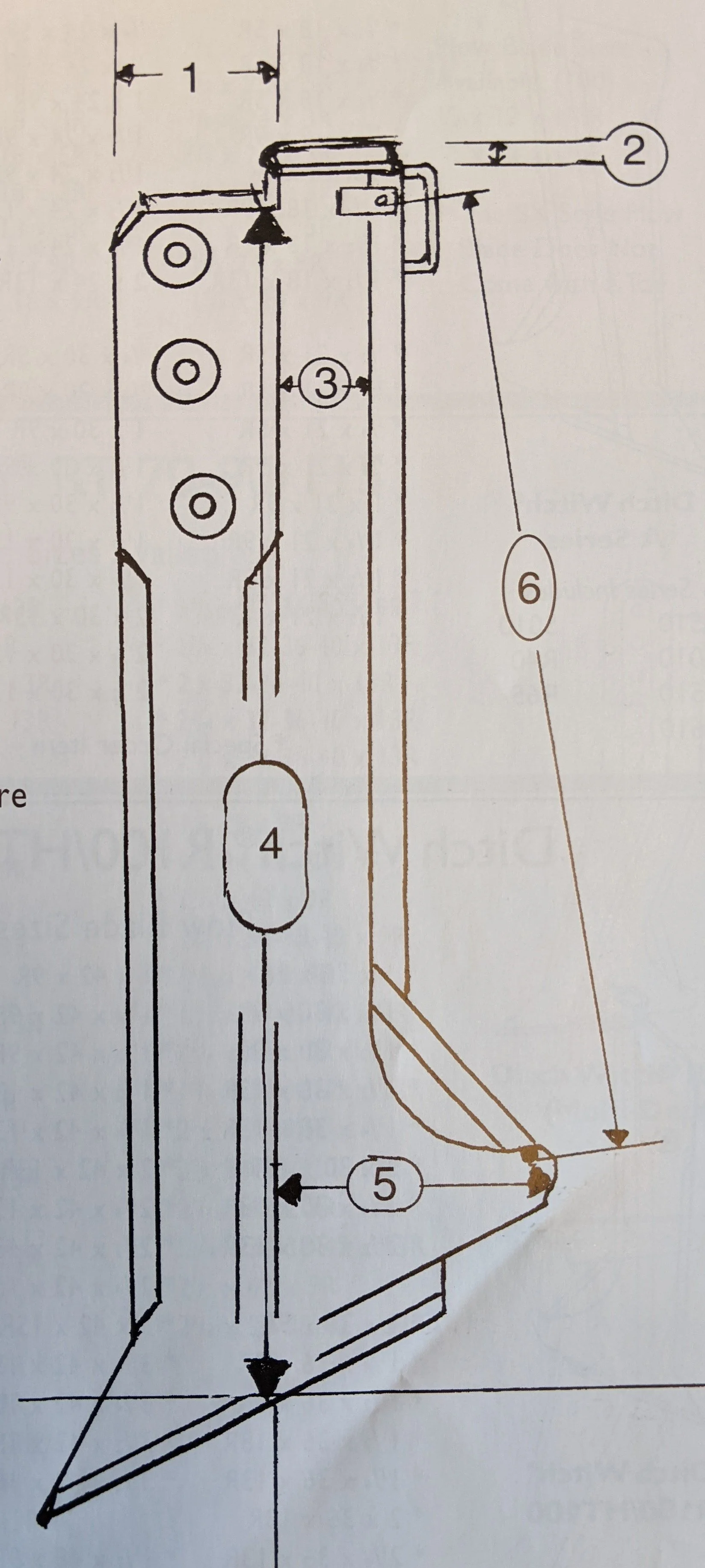

Please Measure the following

1) Number and size of pins or bolts used to mount plow blade to plow unit.

2) The inner width Needed (I.D.) on the chute (Feed Blade Only).

3) The depth of the chute (Feed Blade Only) Note: Let us know if there are multiple Products Being Installed.

4) ***NOT REQUIRED*** At this point. (Custom Blades Only)

5) ***NOT REQUIRED*** At this point. (Custom Blades Only)

6) Depth the material will be buried at (cover depth).

Use the “Quick Quote Form” below to fill in the information. Someone will contact you shortly.

Thank you!

Things you might want to know

YES!

We have made and can make a wide range of custom order blades that serve a wide range of functions. Serrated Edge - Yes! Center Pivot Blades - Yes! Just ask, the answer is likely - Yes!

3 Chute Options for Plowing Multiple Products

The standard - and least expensive option is the extra-deep chute. (The diameter and number of products, decides the depth required.) Note: Remember when ordering cover depths for multiple product’s, we need to know if the cover depth is for the top product or the bottom product.

Extra deep chute - Products stack on top of each other inside chute.

Bolt-in divided chute - Can accommodate individual channels for each product inside one overall chute. The chute pictured has two channels and one divider. The channels can be designated for different sizes or the same, depending on products being installed. (Extra inside depth must be calculated for each diameter chute and also the thickness of the divider piece).

Piggy Back Chutes

Allows blade to be used with only one chute or multiple chutes stacked. Each chute will come with its own gate and if ordered ribbon and or wire tubes. Up to two extra piggy-back chutes can be used on one blade making a total of 3 chutes.

HARDOX Steel!

While most everyone else uses T-1 type steel, All our Cable Plow Blades are manufactured using a Hardox Steel Wear Plate, a proven performer with very high tensile strength!

Product Stamp

Chuted blades are stamped with inside chute width, cover depth of product and radius. They also contain a 4 digit stamp which correlates to our shop work orders. If you are re-ordering a blade and you have this information it can help you and us. The numbers are found on the wing-nut side of the blade and stamped into the chute.

Pull Blade vs Chuted Blade

Pull Blade – Product is attached to 2 ears (the ears/tabs have holes drilled in them- top left side of blade), and then pulled through a trench that is made by the vibrating plow blade. The bullet that the ears are attached to is the same diameter as product being pulled or a little bit bigger.

Chuted Blade – Product is fed through a chute, entering from the top right side of the above blade and existing from the top left side of blade.

What is a Combo Blade?

Combo blades are a combination chuted and pull blade in one blade. The chute is slid up. This allows you to pull in one product and plow in another right above it.